Coibent has been working on international oil company projects for over 15 years, gaining experience as a sub-contractor.

Our focus has been on the following activities:

- Detailed engineering of HVAC & R systems;

- Procurement aimed at purchasing components for HVAC & R systems;

- Construction of customized HVAC & R machinery, in accordance with international standards;

- Cold Room, Freezer room and dry storages;

- Construction of metal air ducts in accordance with national, European and American regulations;

- On site assembly and HVAC system start-up;

- Installation of thermal, acoustic and fire insulation;

- Plumbing and Sewage systems;

- Architectural activity and furnishing of accommodation spaces;

- Installation of Raised Floors.

-

-

Battery Room -Exhaust system

-

-

HVAC Ductwork for UPS module

-

-

HVAC Ductwork in AISI 316L, 2mm thk.

-

-

HVAC Ductwork in AISI 316L, 3mm thk.

-

-

HVAC Ductwork in AISI 316L, 3mm thk.

-

-

HVAC Ductwork in AISI 316L, 3mm thk.

-

-

Exhaust system for Battery Room

-

-

A-60 Fire class Insulation – Technical Room

-

-

Bellypan in Stainless Steel for Fire insulation protection

-

-

Dry food storage_Plug & Play

-

-

A60 Underdeck insulation + InCLAD system

-

-

Special insulation of process piping

-

-

Tests and Commissioning

-

-

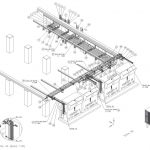

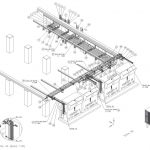

Detailed Engineering

-

-

Interior outfitting – Cold Room TN +4°C

DETAILED ENGINEERING OF HVAC & R SYSTEMS

We can support the Customer during all the construction key phases regarding, for example, the following activities:

- HVAC System, detail drawings;

- Ductwork Shop drawing;

- Detail drawings for the HVAC system erection;

- Interconnecting diagrams;

- Calculations and schemes required by the project specification;

MATERIAL PURCHASING

Knowledge of the products suitable for the purpose and maximum attention in the selection of the same in order to ensure compliance with the project requirements are the prerogatives to be implemented during this phase.

From this phase depends on the success of a project in terms of quality and compliance with the deadlines.

CUSTOMIZED MACHINERY FOR HVAC & R SYSTEM

Each HVAC application in an offshore or onshore environment is different, therefore we build fully customized machinery in order to be compliant with the project requirements in the respect of directives and regulations in force.

COLD ROOM, FREEZER ROOM AND DRY STORAGE

Cold room applications for marine and oil & gas sector for a wide range of temperature to be maintained.

Coibent Plastic offers solution to suit every specific cold room application. The range included both air-cooled and water-cooled condensers.

Every single work comes from a site measurement, a detailed as-built drawing and a special care of the assembly details.

ROOM ENCLOSURE

Self-standing enclosure composed by modular sandwich panels in stainless steel AISI 304 or 316L with inner material in injected polyurethane foam. Other lining material such as fiber-glass, aluminum, plastic coated, etc., are available on request. The modularity of panels employed allows to satisfy any dimensions.

Hinged Doors, or Sliding Door on request, are always designed for heavy duty applications.

Floorings proposed are able to withstand cold or freezing temperatures, easy to clean for hygiene, excellent resistance to heavy loads, non-absorbent and anti-slip. All floors provided are of flame-retardant type to meet SOLAS requirements.

SHELVING

Fully adjustable stainless-steel shelves are designed and fitted to provide the maximum shelving possible within each area. Maximum load per shelf: 100Kg (more robust on request).

Height adjustable feet.

COOLING SYSTEM

SPLIT System based on direct expansion of refrigerant gas. Evaporating unit placed inside the cold room served is connected to the motor-condensing units by copper brazed pipes.

Moto-condensing units are generally of self-standing type complete with the relevant electrical switchboard for feed, control and safety devices. Condensing unit is normally designed to operate in environments up to +45°C, on request it can be designed to work up to +50°C.

In case of Hazardous Area (Ex) condensing unit will be designed and manufactured with certified components suitable for Zone 1 or Zone 2 atmosphere.

Condenser can be of air-cooled or water-cooled type (sea-water type is also available).

Both Evaporating and Condensing Heat exchangers can be provided in copper tubes/aluminum fins or copper tubes/copper fins. For further protection, several types of coatings are available on request.

MAIN FEATURES:

- Evaporating and condensing units available in stainless steel for an excellent corrosion resistance;

- In-built defrost heaters for low-temperature units;

- Safety and Control Devices built-in type;

- Possibility to remote all the signals or commands;

- Reliable automatic room-temperature control;

AIR DUCTS

All of metal ducting, manufactured in our production department, can be designed and constructed in compliance with all the main international standards (SMACNA, DW 144, ISO 15138, SOLAS, EN, etc.).

The range of metal thickness usually worked vary from 0.6mm up to 12mm.

Types of longitudinal and transversal seams are selected for the material, pressure classification and other construction details appropriate for the service, therefore air duct can be realized lock-formed or welded.

Structural penetration according to SOLAS can also be made.

We can provide CAD drawings as the key map with all pieces numbered and the shop-drawing for the duct construction.

We can offer you also Ductwork Leakage test performed according to EN-12237, EN-1507, DW143.

Our goal is to provide Attention to job estimating accuracy, job production quality and on time delivery.

Fabricated Duct Products include:

- Round;

- Rectangular;

- Welded industrial;

- Noise attenuators;

- Specialty;

- Pre-insulated Aluminum Duct

- And more

On request ducts can be supplied already insulated with lots of material as elastomeric foam, stone-wool, cellular glass, and several type of metal cladding as steel sheet, perforated sheet, mesh net, etc.

The Company has qualified welding procedures, certified by R.I.NA, for stainless steel and carbon steel, both according to European standards (EN ISO 15614) and according to American standards (AWS D1.1 and D1.6).

Fabricated metals include:

- Galvanized steel (usually available Z275);

- AISI 304L or AISI 316L Stainless Steel;

- Carbon Steel such as S275, S355, and others;

- Aluminum

- Ask for other solution

Fabricated duct size:

- Wide range of sizes;

- Round duct diameter: up to 1.300mm (fabricated at now in single wall), 3.500mm (fabricated at now in double wall with three sectors coupled by bolting);

- Rectangular: up to 3.000×1.500mm (Fabricated at now in single wall);

- Noise attenuator: up to 3.000×3.000 – at now (Provided dismantled).

ON SITE ASSEMBLY AND HVACR SYSTEM START-UP

The goal of HVAC system is to provide the maintenance of thermo -hygrometric and quality air condition so that to ensure the comfort of people and or the correct operational condition for equipment within the occupied premises.

Given the importance of these systems it is therefore essential that all installations, checks, tests, commissioning and start-up are carried out by skilled personnel both technically, and adequately informed of the safety in the field.

Coibent Plastic has qualified and experienced staff able to manage independently the following activities in the field:

- Assembly and erection of HVACR Equipment;

- Assembly and erection of DUCTWORK;

- Hydraulic and Refrigerant Piping Installation;

- Insulation (PIPEWORK and DUCTWORK, plus relevant equipment and devices);

- Steel Carpentry for system suspensions or for base fixing;

- Electrical connection of the Equipment and Devices;

- Leakage test and mechanical test on refrigerant PIPEWORK;

- Leakage test on DUCTWORK;

- Pre-Commissiong and Commissionig;

- Start-up and tuning;

- Training for the users.

Our staff has the necessary qualification to perform work at height, for first aid at work, for the use of forklifts, aerial platform, bridge crane, etc.

THERMAL, ACOUSTIC & FIRE INSULATION

Solutions for Oil&Gas Sector can include:

- Passive Fire Protection (PFP) of bulkheads and decks to slow or prevent the spread of fire;

- Thermal Insulations for Pipework, Tanks, manifolds, valves and related;

- Acoustic insulation of bulkheads, decks, ductwork, pipework, compressors, and other plants in which noise attenuation is required:

- Cold Insulations;

- Metal Jacketing as mechanical protection of insulations;

- Removable metallic or textile cladding and design of customized items;

- Solutions for Floating Floors A-60;

PLUMBING

FRESH WATER NETWORK

The typical distribution system is designed to provide cold-water distribution, hot water distribution and hot water recirculation for sanitary purpose.

Polypropylene Copolymer – Random (PP-R) is the material usually installed for this application, which is assembled by means of fusion welding of the parts.

The low thermal conductivity and a wide range of use (from -20°C to +95°C) provide a low dispersion of heat. The homogeneous and compact structure makes minimum the pressure drop and prevents occurring phenomena of obstruction caused by deposits of limestone. The high value of insulation reduces the noise and the lightness of pipes and fittings allows an easy handling and installation.

All materials are certified for food uses and are comply with requirements of several classification bodies.

Design of fresh water networks is carried out following European Standards, in accordance with UNI EN 9182

GRAVITY SEWAGE SYSTEM

The typical sewage network we propose in Living Quarter is made by the use of PP (Polypropylene) due to the lightweight, ease of installation, excellent sound insulation, smooth internal surface and high corrosion resistance.

The coupling system mainly used is the push-fit socket fitted with a lip seal that guarantees the hydraulic tightness and free movement of the pipe in the event of thermal expansion. Wide range of fittings are available to connection with other waste system such as cast iron, PE, PVC, etc.

On request, we can provide sewage network based on metal systems, HDPE fusion welded, PVC or other.

Design of discharge lines is carried out following European Standards, in accordance with UNI EN 12056.

FURNISHING

Bespoke solutions modeled around “the human lifestyle”, combining comfort and efficiency, design and daywork duties, ergonomics and lifetime, with particular attention for the respect of applicable rules and specification.

The services covered by Coibent Plastic outfitting department include: interior designing, accommodation panels, ceiling and doors, furnishings and furniture.

Our strength is the furnishing of accommodation spaces such as cabins, mess rooms, day rooms, offices, hospitals, corridors, linen stores, stairways, bridges, lockers, control rooms, galleys, laundry, drying rooms, provisional stores, etc., usually designed and fabricated on turnkey solutions.

Control panels and switchboards as well as other third part supplies are anyhow integrated into the room outfitting and furniture for the best functional and aesthetical result.

FLOORING

Internal room floorings are realized with materials, systems and procedures certified according to the applicable rules covering the full range of marine applications including:

- Marine concrete under layers for wet and dry areas;

- Vinyl Flooring with tiles or rolls, for dry areas;

- Moquette and carpets;

- Resin Flooring for wet rooms and service rooms such as galley, laundry, refrigerated rooms;

- Ceramic tiles Flooring for wet rooms (instead of resin floor) for galley, laundry, etc.;

- Rubber tiles or Mats for electrical rooms;

- Raised Floor with removable tiles for control rooms and wheelhouse;

- Skirting and finishing profiles in accordance with the standard of the room in which are installed;

- Wood and Composite Decking of work vessels like supply vessels, anchor handling tug, etc.

RAISED FLOOR

Raised Floor is a modular solution to have a fast and easy access in the underfloor area allowing the refurbishment or reconfiguration of spaces with minimum disruption.

This floor is very common in electrical rooms, control rooms, technical room, data center, anyway it is always recommended in all those rooms where its characteristic is necessary.

A variety of special bonded finishes are available.

It can be fitted or directly on beam steel structure or on its pedestal structure available in different heights up to 150cm and beyond.

High load capacity with easy and flexible installation system.

Its structure allows an easy installation of walkable grilles of multiple brand for HVAC systems

The Raised floor supplied by us are selected among the most important international producers to guarantee the highest quality and short time delivery.